Categorie prodotti

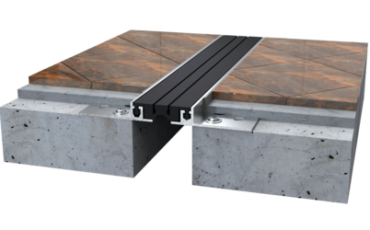

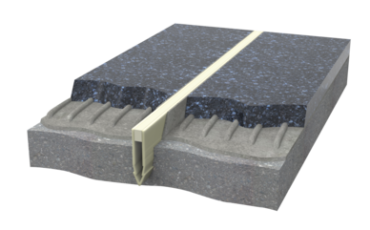

Giunti per pavimenti

Giunti di dilatazione per pavimenti interni ed esterni, anche per applicazioni sul finito

Visualizza profili

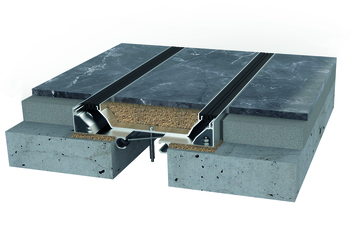

Giunti per carrelli elevatori

Giunti di dilatazione per pavimenti con elevata portata, idonei al passaggio di carrelli elevatori

Visualizza profili

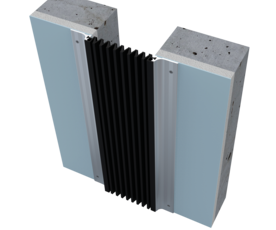

Giunti per zone sismiche con elevato movimento

Giunti di dilatazione con elevato movimento, ideali per l'applicazione in zone sismiche

Visualizza profili

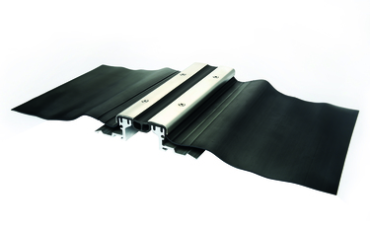

Giunti impermeabili per parcheggi e coperture

Giunti di dilatazione per pavimenti e coperture a perfetta tenuta d'acqua

Visualizza profili

Giunti per facciate, pareti e soffitti

Giunti di dilatazione per facciate esterne, pareti interne e soffitti su superfici finite o sotto intonaco

Visualizza profili

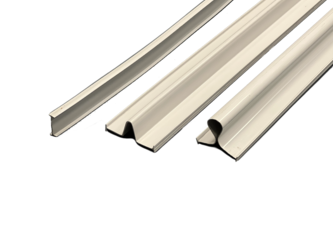

Giunti elastici di frazionamento di pavimentazione

Giunti elastici di frazionamento per tutti i tipi di pavimentazione, in PVC, alluminio, acciaio e ottone

Visualizza profili

Barriere tagliafuoco

Barriere tagliafuoco per giunti di dilatazione a parete e solaio

Visualizza profili

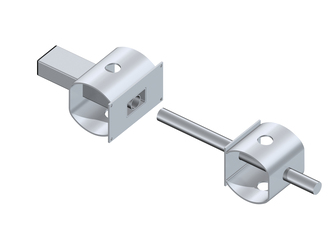

Connettori a taglio

Connettori a spinotto singolo o doppio per il trasferimento degli sforzi di taglio in presenza di giunti di dilatazione

Visualizza profili

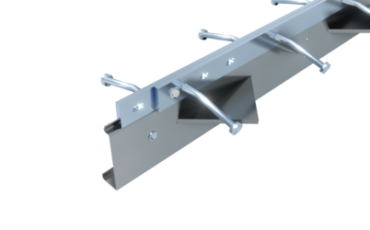

Giunti per pavimentazioni industriali

Giunti di costruzione per riprese di getto in pavimentazioni industriali in calcestruzzo

Visualizza profili

Giunti per impalcati stradali e dispositivi di appoggio

Giunti di dilatazione per ponti ed impalcati stradali, apparecchi di appoggio elastomerici (EN 1337-3)

Visualizza profili

Giunti di tenuta per pannelli prefabbricati

Giunti di tenuta per pannelli prefabbricati in PVC rigido

Visualizza profili

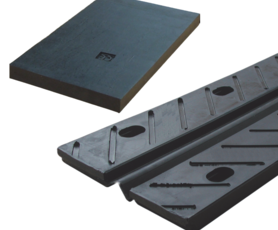

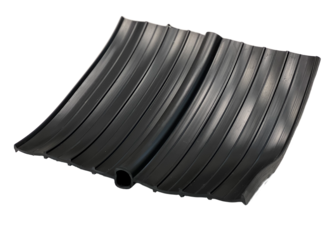

Waterstop

Giunti di tenuta per riprese di getto di c.a. in opera e cordoli bentonitici idroespansivi

Visualizza profili

Contattateci per una ottimale risoluzione alle vostre esigenze

La nostra conoscenza nell'impiego delle soluzioni tecniche proposte

è il risultato di un ampio lavoro di ricerca e di una lunga esperienza

Contattateci

è il risultato di un ampio lavoro di ricerca e di una lunga esperienza

Scarica il catalogo prodotti

Scarica una copia del catalogo prodotti completo

in formato PDF per la consultazione offline

Scarica

in formato PDF per la consultazione offline