SERIE BENTOJOINT

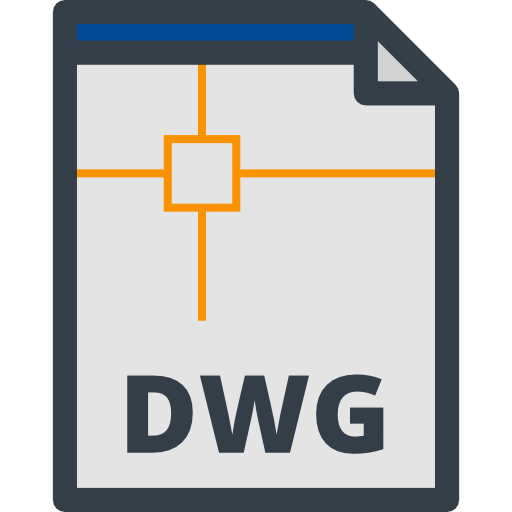

Cordolo “waterstop” idroespansivo a base di bentonite sodica. La bentonite sodica o montmorillonite è una particolare argilla naturale con spiccate caratteristiche colloidali. La sua qualità fondamentale è quella di rigonfiare in acqua fino ad occupare un volume parecchie volte superiore a quello del materiale secco e di dar luogo alla formazione di gel tixotropici anche con rapporti bentonite/acqua molto bassi. La capacità della bentonite di rigonfiare in acqua è dovuta allo scambio ionico causato dalla presenza di cationi scambiabili negli strati reticolari della montmorillonite. L’idratazione delle lamelle di bentonite forma un reticolo caotico che sigilla nei confronti delle infiltrazioni d’acqua. Infatti i minuscoli fiocchi di bentonite dispersa, penetrano nelle crepe e nelle cavità e premendo contro il calcestruzzo impediscono all’acqua di infiltrarsi. La capacità di sigillatura aumenta all’aumentare della pressione idrostatica esercitata nei confronti della bentonite, in quanto l’incremento di pressione sulle lamelle di bentonite produce un effetto valvola a sfera (maggiore è la pressione più è compatta la sigillatura). Il processo di espansione è reversibile e non produce implicazioni sul possibile impiego del cordolo Bentojoint. Una volta posato in opera, il cordolo Bentojoint non si sposta né si deteriora.

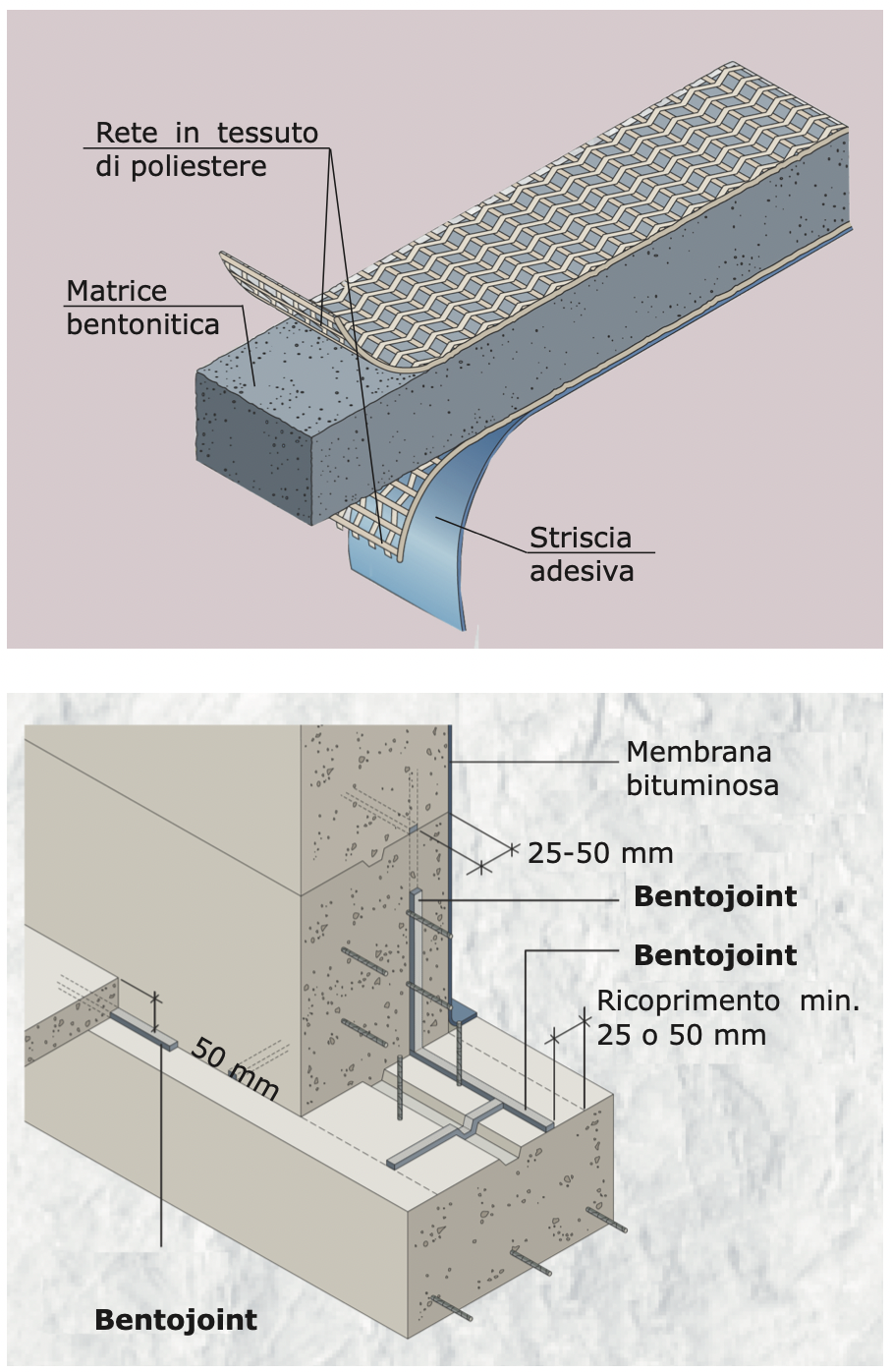

Il cordolo Bentojoint può essere utilizzato nella realizzazione di strutture in calcestruzzo armato gettate sia in opera che prefabbricate; in particolare è adatto per le applicazioni in riprese di getto (sia verticali che orizzontali), volte sotterranee, tunnel, impianti per il trattamento delle acque, impianti di depurazione.

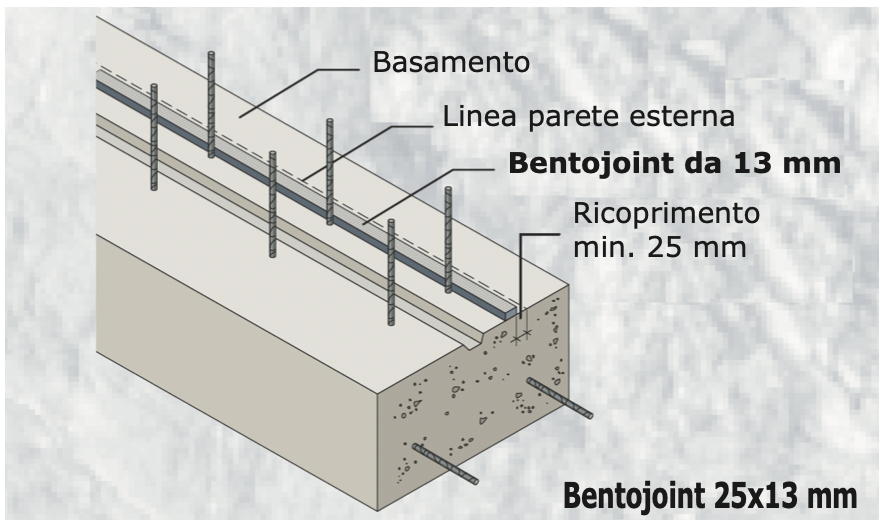

Cordolo Bentojoint sez. 25×13 mm, confezionato in cartoni da 61,00 m (10 rotoli da 6,10 m) oppure in bancali da 30 cartoni (1830 m)

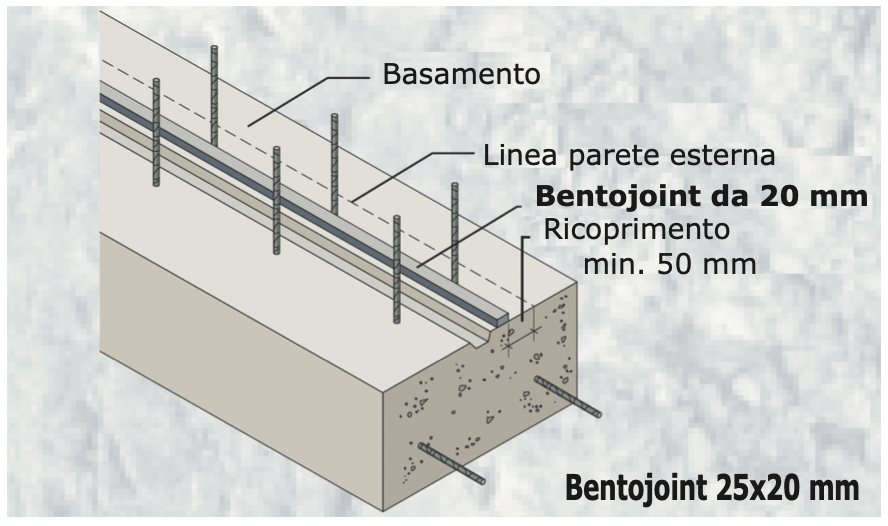

Cordolo Bentojoint sez. 25×20 mm, confezionato in cartoni da 40,00 m (10 rotoli da 4,00 m) oppure in bancali da 30 cartoni (1200 m)

1,75 gr/cm³ (ASTM D-71)

100 °C (ASTM D-30)

nessuna (ASTM D-93-97)

da -18 °C a 110 °C

da -40 °C a 110 °C

Grigio

31,5 kg

50% (ASTM D-638 Tipo 4)

Nessuna Infiltrazione (ASTM D-751 Metodo A)

Per informazioni dettagliate in merito alla posa in opera fare riferimento alla scheda tecnica o contattare il nostro ufficio tecnico.

0.35

3.50

24

24

nowater

0.70

7.04

24

48

nowater

1.05

10.54

24

72

nowater

1.40

14.05

24

96

nowater

1.75

17.58

24

120

nowater

2.10

21.09

24

144

nowater

2.45

24.59

24

168

nowater

2.81

28.13

24

192

nowater

3.16

31.63

24

240

nowater

Disponibili prove eseguite dal Centro di Certificazione e Analisi Comportamentale CSI di Bollate (MI)