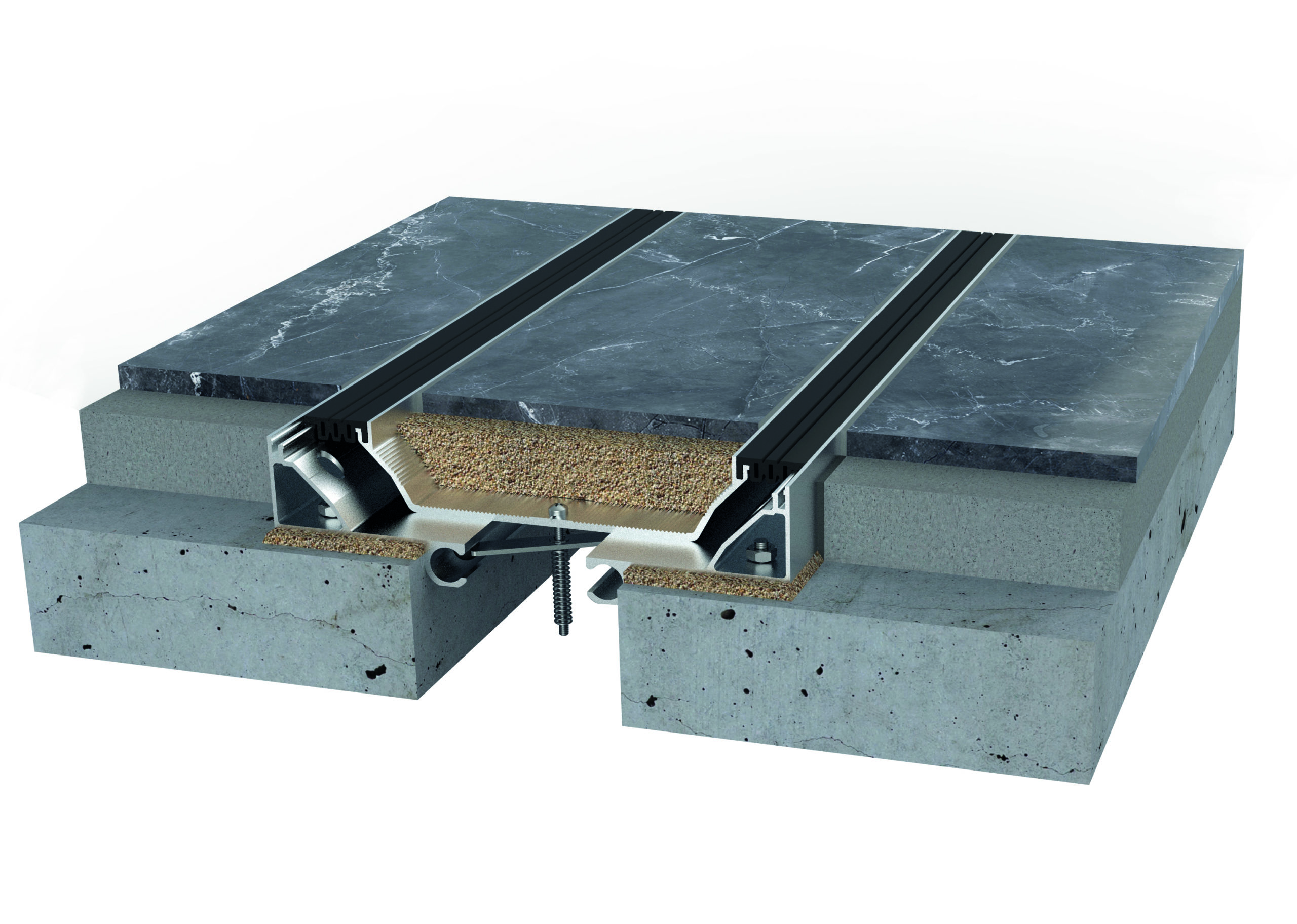

SERIE JSDP .../33/45 - 60

Profilo portante in alluminio. Inserti elastomerici in vista flessibili di elevata qualità, di lunga durata, resistenti all’abrasione, agli agenti atmosferici, alle temperature (da -40°C a +120°C).

Ideale per applicazione con tutti i tipi di finiture (granito, marmo, ceramica, vinilico e PVC). Disponibile anche nella sua versione angolare K.

Progettato per giunti di dilatazione di grandi dimensioni e dimensionato per movimenti molto ampi, ideale in zone sismiche

Inserti elastomerici sostituibili in ogni momento

Superficie visibile ridotta ai soli inserti elastomerici

3 m

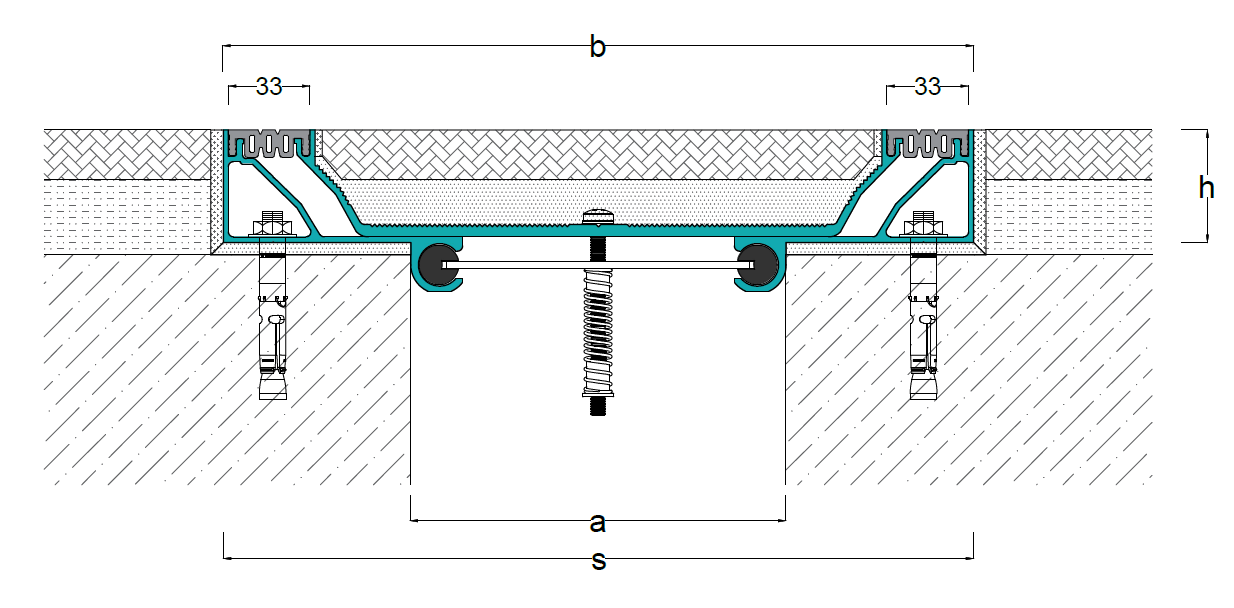

max [mm]

a

totale [mm]

Δmax

visible [mm]

b

totale [mm]

s

profilo [mm]

h

JSDP 100/33/45

100

100 (± 50)

250

250

45

Pedonale/Lavapavimenti

JSDP 150/33/45

150

140 (± 70)

300

300

45

Pedonale/Lavapavimenti

JSDP 200/33/45

200

180 (+100/-80)

400

400

45

Pedonale/Lavapavimenti

JSDP 250/33/60

250

250 (± 125)

480

480

60

Pedonale/Lavapavimenti

JSDP 300/33/60

300

300 (± 150)

600

600

60

Pedonale/Lavapavimenti

JSDP 350/33/60

350

350 (± 175)

650

650

60

Pedonale/Lavapavimenti

JSDP 400/33/60

400

375 (+175/-200)

700

700

60

Pedonale/Lavapavimenti

JSDP 450/33/60

450

400 (+175/-225)

750

750

60

Pedonale/Lavapavimenti

JSDP 500/33/60

500

425 (+175/-250)

800

800

60

Pedonale/Lavapavimenti