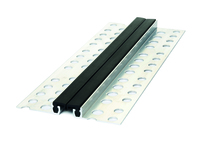

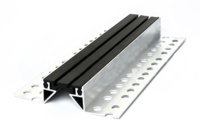

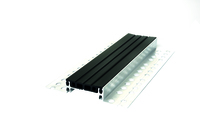

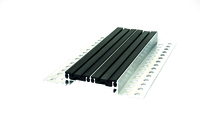

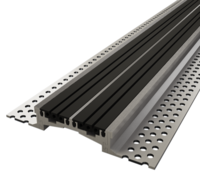

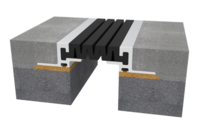

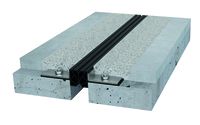

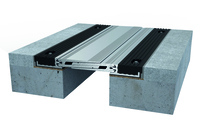

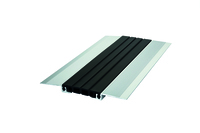

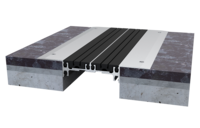

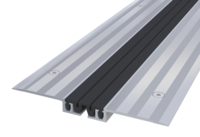

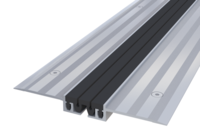

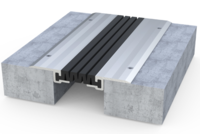

Giunti per pavimento

Profilo

Larghezza

[mm]

[mm]

Movimento

totale [mm]

totale [mm]

Capacità

di carico

di carico

Documentazione

tecnica

tecnica

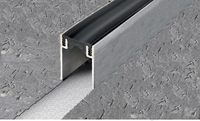

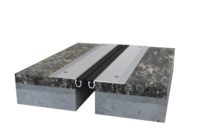

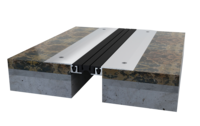

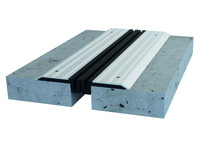

Giunti per pavimento finito

Profilo

Larghezza

[mm]

[mm]

Movimento

totale [mm]

totale [mm]

Capacità

di carico

di carico

Documentazione

tecnica

tecnica

Get a Quote

Get a free quote for your industrial or engineering business solutions, We are here 24/7.