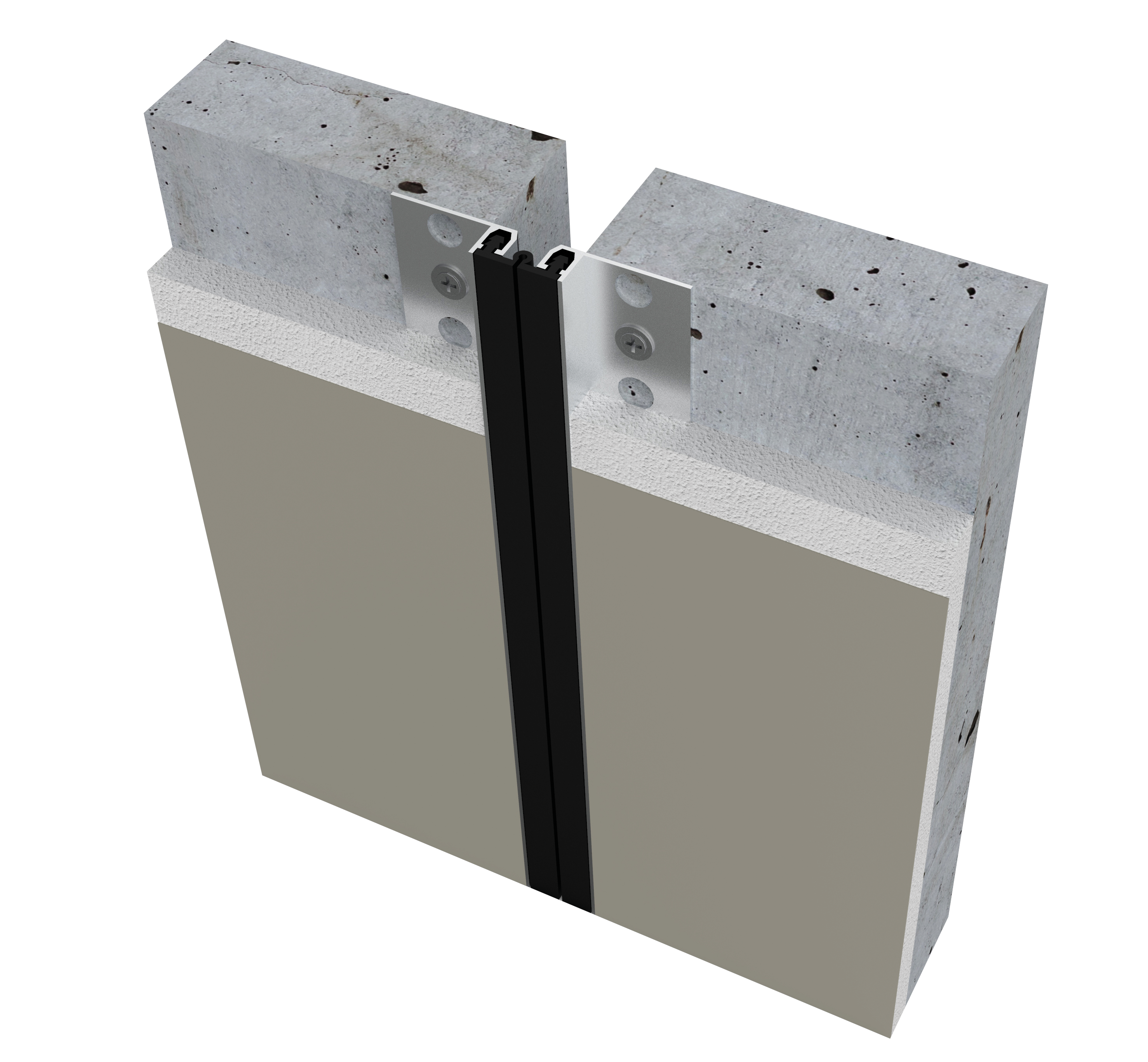

SERIE JD 25/...

Giunti per facciate, pareti e soffitti : JD 25/...

Torna all'indice di categoria

Materiali:

Profilo portante in alluminio con ali di fissaggio preforate che consentono un ancoraggio ottimale al supporto. Inserto elastomerico centrale flessibile di elevata qualità, di lunga durata, resistente all’abrasione, agli agenti atmosferici, alle temperature (da -40°C a +120°C).

Caratteristiche particolari:

Inserto centrale flessibile sostituibile in qualsiasi momento

Il profilo assorbe grandi movimenti

Per ogni tipologia di giunto è disponibile la sua versione angolare

Adatto per applicazioni sotto intonaco e per cartongesso o ceramica

Colori

Lunghezza di produzione

3 m

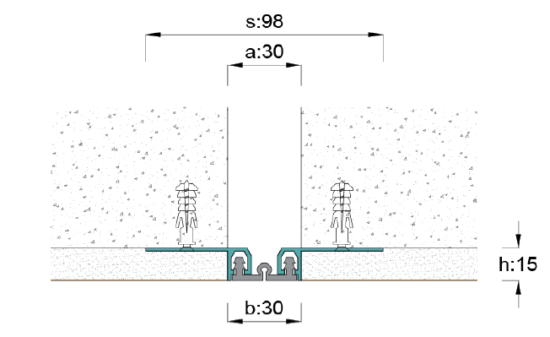

JD 25/30

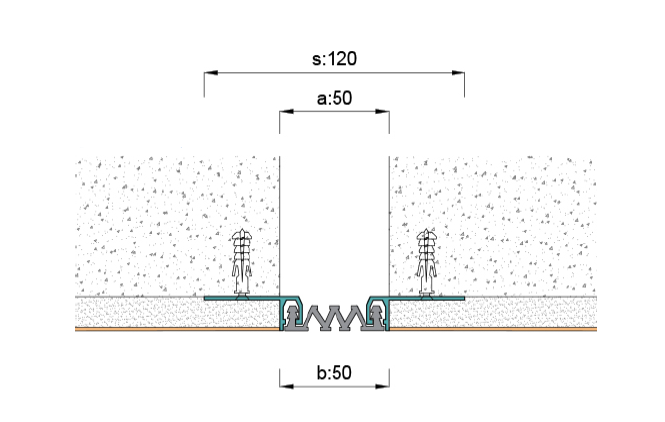

JD 25/50

JD 25/80

JD 25/100

Dati Tecnici

Profilo

Larghezza

max [mm]

a

max [mm]

a

Movimento

totale [mm]

Δmax

totale [mm]

Δmax

Larghezza

visible [mm]

b

visible [mm]

b

Larghezza

totale [mm]

s

totale [mm]

s

Altezza

profilo [mm]

h

profilo [mm]

h

JD 25/30

30

20 (± 10)

30

98

15

JD 25/50

50

40 (± 20)

50

120

15

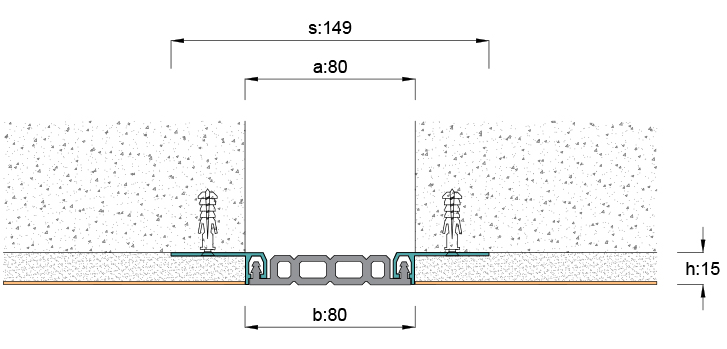

JD 25/80

80

20 (± 10)

80

149

15

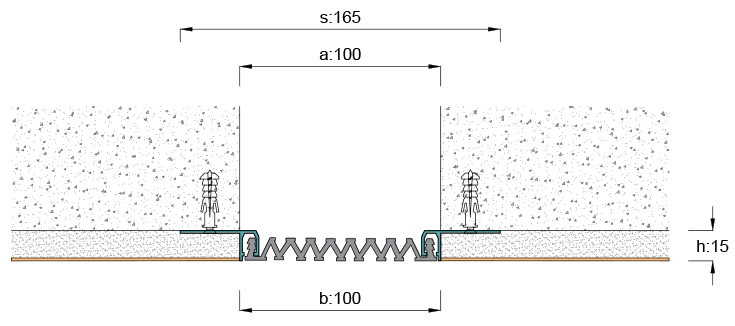

JD 25/100

100

100 (± 50)

100

165

15

Get a Quote

Get a free quote for your industrial or engineering business solutions, We are here 24/7.